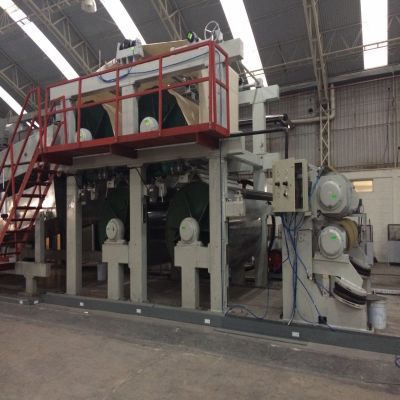

1 overall machine adopt 6frequency motor control, overall machine tension (unwinding, coating, traction, rewinding) adopt JAPANESE MITSHUBISHI PLC to control tension automatic , through man machine interface touch screen to control and display to improve machine tension reliability.

2 independent unwinding frame, adopt magnetic powder auto-control tension.

3 gravure coating method, coating doctor blade shaft adopt heavy double shaft machine independent moving, blade adjust by manual with pneumatic, angle adjust freely, coating quantity depend the mesh of gravure roller, different coating quantity can change different mesh gravure roller.

4 two layer oven is uper 10m for 5section independently control, down layer oven 8m for 4section independently control, heating adopt electric, hot air intake drying system, heater outset,heating pipe adopt stainless steel with cooling fin type,adjustable inner cycle air intake and out device, air intake and out with strong air , dry thoroughly.

5 oven inner guide wheel is active synchronous with the mainframe, drive adopt synchronous belt drive guide wheel to assure synchronous to reduce material stretch and deformation, cylinder pneumatic open oven and film pass operation panel so that worker can work very easily.

6 the tension between coaitng roller and traction steel roller adopt float swing arm by PLC auto-control.

7 auto-length and speed meter device.

8 webguide adopt EPC air sensitive register to assure the trimness when rewinding.

9 rewinding and unwinding adopt key type airshaft for easily operate when loading and unloading the material, air shaft take in/off adopt safety lock type.

10 high presicion up press traction device, steel roller cooling adopt water cycle to make the film surface more smooth and neat.to reach good cooling effect.

11 rewinding frame is electric rotation double station, rewinding adopt frequency motor, vector inverter by PLC control.

Process:

unwinding roll → scrape-knife coating device → three drying ovens (four meters each drying oven) →scrape-knife coating device → four drying ovens (four meters each drying oven) → back wet device → 3-φ1350 debugging mode Cylinder dryer→two roll calender machines →level rewinding roll device, please see process flow diagram

Installed Introduction and Scope of supply:

Automatic unwinding & feed paper device is composed by double rotary paper frame and continous paper feed device. Double rotary paper frame is composed by frame, swing arm, worm gear box, rotary driven shaft, air swelling shaft, paper roll brakes device and guide roller. The continous paper feed device is composed by the paper receiving arm, compression roller, cutting paper knives and paper guide roller. The system is controlled by compressed air system and electrical system.

Qingdao Jieruixin Technology and Machinery CO,. Ltd.

Qingdao Jieruixin Technology and Machinery CO,. Ltd.